0

0

Compressed Air System

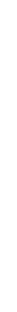

DTS V Series (DTS V 410~1470)

During heat regeneration, ambient air is drawn in by a vacuum pump/blower, heated to approximately 160°C and fed through the regenerating vessel in order to regenerate the desiccant. The hot air removes the moisture from the desiccant and releases it to the environment at the outlet.

If there is no suitable ambient air available, expanded compressed air can be used as an alter- native. For DTS V series dryers, the change interval between adsorption and regeneration is 6 hours at nominal conditions. The cycle time is therefore 12 hours.

Specification:

| Product Type | DTS 45 ~ 1470 V |

| Max. Working Pressure | 4 ~ 11 Bar |

| FAD | 410 ~ 14,700 m³/h |

| Connection | 1 1/2" ~ 8" |

Looking for a Trustworthy & Reliable Partner?

Are you looking for a trustworthy & reliable partner who can consult, design, supply, install and maintain all the trades of compressed air system, fluid dynamic system & HVAC system for industrial projects?

request a brochure

request a brochure